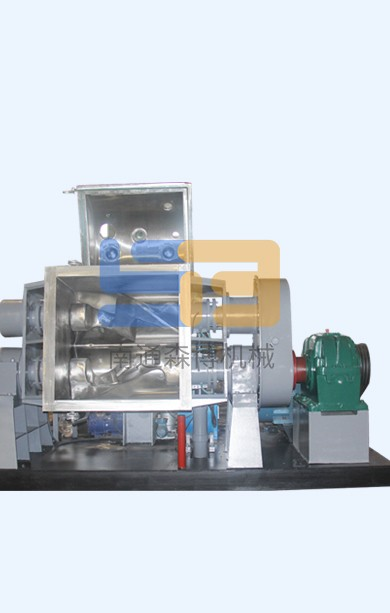

This series of products are divided into ordinary type, pressure type, vacuum type. There are two heating methods: electricity and steam, and water cooling. The discharging methods include hydraulic cylinder tilting, ball valve discharging, and screw extrusion. Vacuum kneaders can be customized according to user needs. They are widely used in silicone rubber, Pigment, ink, gum base, carbon, food, medicine and other industries. The mixing tank and paddle of this equipment are made of stainless steel. The mixing tank jacket can be designed in the form of electric heating, steam heating or water cooling. The discharging methods include hydraulic cylinder turning, screw extrusion and lower discharging. (Can be customized according to user needs)

| Model | NH-500 | NH-600 | NH-800 | NH-1000 | NH-1500 | NH-2000 | NH-3000 | NH-5000 | NH-8000 | |

| Volume (L) | 500 | 600 | 800 | 1000 | 1500 | 2000 | 3000 | 5000 | 8000 | |

| Stirring speed (rpm) | 33、23 | 33、23 | 35、22 | 37、21 | 37、21 | 35、25 | 30、16 | 30、16 | 30、16 | |

| Host power (KW) | 18~22 | 22~37 | 30~45 | 55~75 | 55~75 | 75~90 | 75~110 | 110~200 | 160~250 | |

| Heating method | Steam: Pressure (MPA) | 0.3 | ||||||||

| Electric heating: power (KW) | Customized according to customer requirements | |||||||||

| Vacuum degree (MPA) | -0.094(Vacuum type kneader) | |||||||||

| Pressure (MPA) | 0.45(Pressure type kneader) | 0.35(Pressure type kneader) | ||||||||